Water well is the main facility for drawing groundwater resources. It is usually formed by digging or drilling a hole vertically downwards from the ground to reach the aquifer, and laying well frames or installing well pipes around the hole wall. The construction of water wells is divided into various types due to different conditions such as formation conditions, water demand, construction methods, such as deep and shallow wells, group wells, small tube wells, radiation wells, horizontal wells, etc.; and the cost, pumping volume, pumping level and The suitable geological and hydrological conditions are also different. There are two types of water wells according to their uses. One is pumping wells for general extraction of groundwater, and the other is monitoring wells for monitoring the quality of groundwater.

According to Article 60 of the Water Conservancy Law, "within 15 days after the completion of the water test of the well sinking project, the stratum map, pumping equipment and pumping test records shall be reported to the competent authority." However, ordinary drilling operators have limited funds for drilling shallow wells. They usually only drill to aquifers that meet their water intake based on their experience. They have not carried out relevant plans or tests, and have often failed to declare relevant formation and water test data to relevant units. The construction of deep wells is usually expensive, so its planning and design must be very careful. It is necessary to collect hydrogeological data, water quality considerations, water output estimation, well position and depth determination, water well type, and possible interference from adjacent wells. Consider before planning the well design.

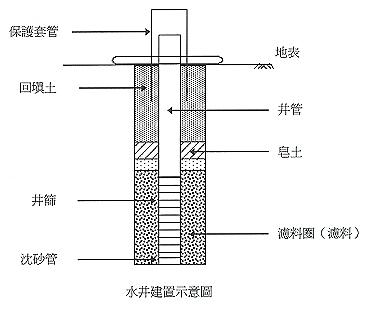

The complete water well body mainly includes well pipes, filter rings, well screens and sand sinking pipes (as shown in the picture). The well pipe is the most important part of the well body. It should have sufficient strength to withstand the lateral earth pressure of the surrounding stratum, the hydrostatic pressure of the underground aquifer and the external construction force when the pipe is run down. At the same time, it must not easily interact with the stratum material, other The fluid reacts chemically. If the well pipe cannot withstand these pressures, the well body will easily collapse, and if it easily reacts with other substances, it will be prone to corrosion or fouling. Therefore, its material is often an important factor affecting the service life of the well.

The filter pack is to prevent the fine-particle soil in the aquifer from flowing into the well pipe with groundwater and causing soil loss, or blocking the filter pipe so that the groundwater cannot flow smoothly into the well pipe. Therefore, after the well pipe is buried, it will The filter material is filled between the hole and the well tube to form a filter material circle (or gravel pack, as shown in the figure). The main function of the screen is to provide a channel for the groundwater passing through the filter ring to enter the well pipe. The length of the well screen and the size of the screen hole affect the amount of water output, and vice versa, it also affects the overall strength of the well pipe. There are many types of well screens, including slit type, drilling and winding type, shutter type... etc. The grit pipe is a section of the well pipe at the bottom of the well, which is connected to the bottom of the filter pipe at the bottom layer and is placed deep in the impermeable layer. The bottom of the pipe is closed and not connected to the outside of the well. Its main function is to prepare fine particles for sedimentation to invade the well body so as not to block the well pipe.

The function of Bentonite is to block and isolate the connection between the monitored aquifer and other aquifers, to prevent rainwater, surface water or groundwater from different aquifers from mixing, and affect the accuracy of water level or water quality monitoring.

Reference materials:

1. Water Resources Department Taiwan Area Groundwater Communication Groundwater Tips-Well Pipe Material (October 2000).

2. Water Resources Department Taiwan Area Groundwater Communication Groundwater Tips-Filter Circle (December 2000).

3. Specification for groundwater quality monitoring wells, Environmental Protection Agency, 2000.

4. Groundwater, Cao Yisong, 1993. 5. Handbook of Wells, Taiwan Sugar Company, 1976.

Source: National Cheng Kung University's Stratigraphic Subsidence Prevention and Control Service Team "e Xunbao" April 4th, 2001, Issue 016

According to Article 60 of the Water Conservancy Law, "within 15 days after the completion of the water test of the well sinking project, the stratum map, pumping equipment and pumping test records shall be reported to the competent authority." However, ordinary drilling operators have limited funds for drilling shallow wells. They usually only drill to aquifers that meet their water intake based on their experience. They have not carried out relevant plans or tests, and have often failed to declare relevant formation and water test data to relevant units. The construction of deep wells is usually expensive, so its planning and design must be very careful. It is necessary to collect hydrogeological data, water quality considerations, water output estimation, well position and depth determination, water well type, and possible interference from adjacent wells. Consider before planning the well design.

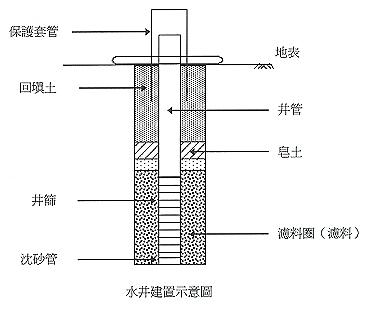

The complete water well body mainly includes well pipes, filter rings, well screens and sand sinking pipes (as shown in the picture). The well pipe is the most important part of the well body. It should have sufficient strength to withstand the lateral earth pressure of the surrounding stratum, the hydrostatic pressure of the underground aquifer and the external construction force when the pipe is run down. At the same time, it must not easily interact with the stratum material, other The fluid reacts chemically. If the well pipe cannot withstand these pressures, the well body will easily collapse, and if it easily reacts with other substances, it will be prone to corrosion or fouling. Therefore, its material is often an important factor affecting the service life of the well.

The filter pack is to prevent the fine-particle soil in the aquifer from flowing into the well pipe with groundwater and causing soil loss, or blocking the filter pipe so that the groundwater cannot flow smoothly into the well pipe. Therefore, after the well pipe is buried, it will The filter material is filled between the hole and the well tube to form a filter material circle (or gravel pack, as shown in the figure). The main function of the screen is to provide a channel for the groundwater passing through the filter ring to enter the well pipe. The length of the well screen and the size of the screen hole affect the amount of water output, and vice versa, it also affects the overall strength of the well pipe. There are many types of well screens, including slit type, drilling and winding type, shutter type... etc. The grit pipe is a section of the well pipe at the bottom of the well, which is connected to the bottom of the filter pipe at the bottom layer and is placed deep in the impermeable layer. The bottom of the pipe is closed and not connected to the outside of the well. Its main function is to prepare fine particles for sedimentation to invade the well body so as not to block the well pipe.

The function of Bentonite is to block and isolate the connection between the monitored aquifer and other aquifers, to prevent rainwater, surface water or groundwater from different aquifers from mixing, and affect the accuracy of water level or water quality monitoring.

Reference materials:

1. Water Resources Department Taiwan Area Groundwater Communication Groundwater Tips-Well Pipe Material (October 2000).

2. Water Resources Department Taiwan Area Groundwater Communication Groundwater Tips-Filter Circle (December 2000).

3. Specification for groundwater quality monitoring wells, Environmental Protection Agency, 2000.

4. Groundwater, Cao Yisong, 1993. 5. Handbook of Wells, Taiwan Sugar Company, 1976.

Source: National Cheng Kung University's Stratigraphic Subsidence Prevention and Control Service Team "e Xunbao" April 4th, 2001, Issue 016